TECHNOLOGY

When you need to move a lot of people in a little time – economically, comfortably and reliably – you need a traction elevator.

Ideal for high and medium-rise buildings. Traction elevator delivers smooth, quick acceleration, energy effciency and attractive cost for high-rise buildings. Especially, these lifts impress with their versatility, power and speed.

A superior combination of fexibility and performance. To create the highest quality traction elevators, our designers and engineers put their technological creativity to its full potential. Our traction elevators combine the latest digital technology with world-renowned construction to achieve a new level of precision, energy efficiency, safety, and reliability

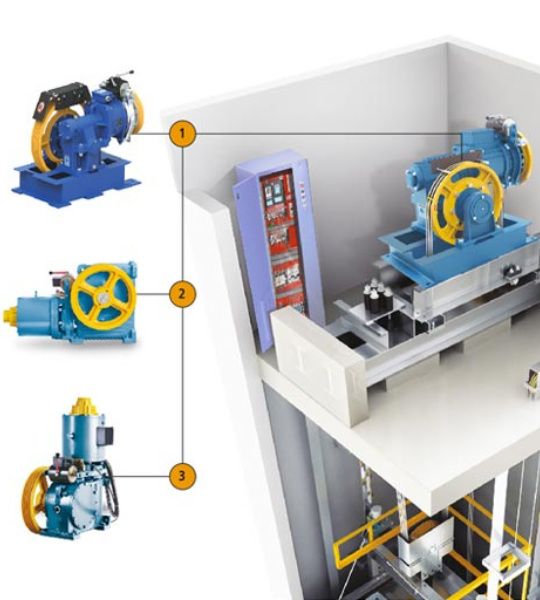

3 DIRECTIONAL MACHINE INSTALLATION

(Innovative Space)

It saves energy and space.

JUSTIN intelligent machine room – less passenger elevator knows very well of environment protection concept. It saves energy and reduces consumption.

It enhances design freedom. Compared with geared elevators with the same load rating, it saves over 33% of energy.

JUSTIN intelligent machine room-less passenger elevator breaks through a must of machine room. It provides limited space in modern buildings with perfect creativeness.

Low noise, tiny vibration

Comprising the best components, the reasonable structure design and the high technology of vibration reducing and noise controlling can disperse and counteract the car’s irregular vibration, making the car run quietly.

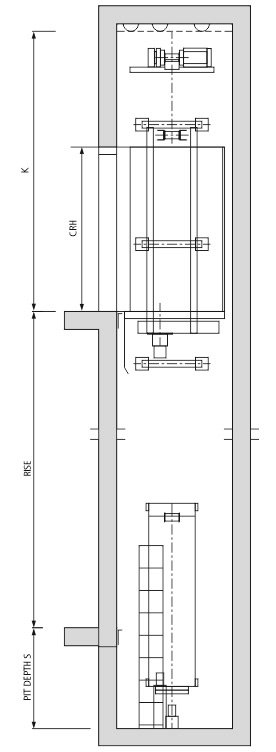

Hydraulic elevators are powered by a piston that travels inside a cylinder. An electric motor is used to pump hydraulic oil into the cylinder to move the piston, thus smoothly lifting the elevator cab. Electrical valves control the release of the oil for a gentle descent.

Hydraulic elevators are used extensively in villas or buildings up to a ve stories high. These elevators do not use the large overhead hoisting machinery the way geared and gearless traction systems do.

The power pack is placed on the lowest landing on any side of the elevator hoistway. The minimum overhead dimensions required are 3000mm and the pit required is 300mm.

- The lift need to be operated by authorized personnel’s only

- The “dead stick” type control should return to ‘neutral’ or ‘off’ position when released.

- The hydraulic pressure should never exceed the recommended level.

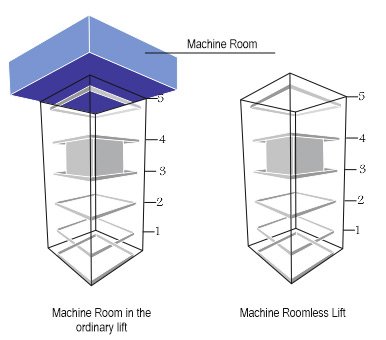

( Machine Roomless Elevator )

The Belt Drive Elevator delivers superior performance in a space-saving design. Coated steel belts have a significantly smaller bending radius as compared to wire ropes. The steel belts also last longer than conventional steel ropes, without the need for lubrication.

The suspension Traction Media (STM) enables a smaller traction diameter of 110mm, Traction into a smaller motor size.

The suspension Traction Media (STM) enables a smaller traction diameter of 110mm, Traction into a smaller motor size.

Space

Effciency

Our patented flat-belt technology, pioneering drives, and gearless machines make the elevator among the most energy-efficient elevators on the planet.

Comfort

Our systems minimize noise and vibration and render the elevator’s movement barely perceptible, giving passengers what they’re looking for a quiet, comfortable ride.

Reliable

Built in ISO-certified factories, with a lifetime of service in mind, every elevator offers superior reliability.

(Machine Roomless Elevator)

The Machine room-less elevator also referred to as the MRL Elevator can be used if there is no dedicated machine room space available. Machines and governors are located in the hoistway and controllers are located in proximity to the exterior front wall of the hoistway.

There can be either with geared or gearless machines depending on the availability of the overhead and pit areas of the hoistway.

Gearless technology is usually recommended as it is more energy-efficient and occupies a smaller space.

It saves 25% of total elevator equipment area. It reduces 40% of space occupation.